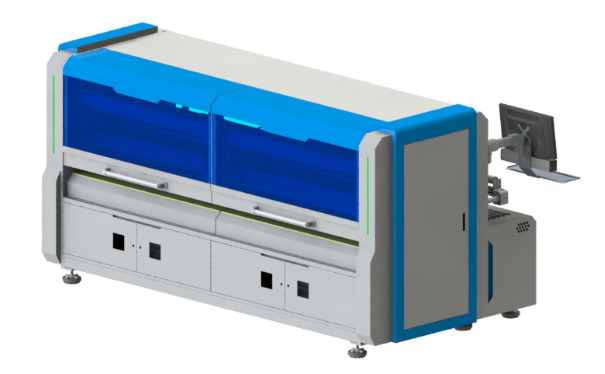

Flexible Corrugated Carton Box Making Machine for Multiple Short-Run Orders

In the fast-changing world of packaging, flexibility and speed are becoming more valuable than ever. Many box factories today face small batch or custom-size orders that traditional carton production lines cannot handle efficiently. The HD2508-U Flexible Corrugated Carton Box Making Machine provides the perfect solution — a digital, fully automatic system designed for short-run and on-demand carton production.

What Is a Corrugated Box Making Machine?

A corrugated box making machine is an automated system that cuts, slots, creases, and shapes corrugated or honeycomb board into boxes. Unlike traditional die-cutting machines, which rely on physical molds, the HD2508-U uses CNC-controlled cutting knives and software-driven templates. This box making machine can make more than 100 types of boxes and you can diy as well.

This means users can simply enter dimensions or import a data file,deisgn by themselves, and the machine will automatically adjust the knives and pressure wheels to produce boxes of different sizes and types — without changing any tools or dies. For factories handling multiple SKUs or short production runs, this digital flexibility saves hours of setup time and dramatically reduces waste.

How the HD2508-U Box Making Machine Works

The HD2508-U box making machine combines several core packaging processes into one intelligent machine:

- Automatic Feeding: Corrugated cardboard sheets are smoothly fed into the system by a precision front-edge feeder.

- Slotting and Creasing: The system can create folding lines and slots according to the box type.

- Longitudinal and Cross Cutting: Knives equipped with an automatic sharpening function ensure consistent cutting accuracy and long tool life.

- High-Frequency Oscillating Knife: Allows for custom openings, such as handle holes, vents, or irregular shapes, expanding design flexibility.

- Optional Modules: Cold-glue box forming and flexo printing modules can be added to turn raw sheets into printed and glued cartons in one pass.

Each process is synchronized under intelligent software control, ensuring precision alignment even for large-format or thick honeycomb board.

Key Advantages Over Traditional Systems

- No Die Required: Eliminates costly mold production and setup.

- Quick Job Changeover: Digital parameter adjustment takes just seconds.

- High Precision: CNC control and vibration knife deliver smooth, clean edges.

- Multi-Function Integration: Cutting, creasing, slotting, punching — all in one machine.

- Safety and Stability: Enclosed structure with automatic power-off protection ensures operator safety.

- One-Person Operation: Designed for simplicity, reducing labor costs and operator training time.

In short, the HD2508-U box making machine transforms the way carton factories handle diverse and unpredictable orders — replacing slow manual setups with smart digital automation.

Applications of Box Making Machine

- Furniture & Cabinet Packaging: Automatically create boxes for doors, panels, and custom-sized components.

- E-Commerce Fulfillment: Produce custom boxes that fit each shipment perfectly, reducing void fill and shipping costs.

- Logistics & Warehousing: Prepare various box types for seasonal or promotional packaging needs.

- Printing & Converting Plants: Integrate the HD2508-U as a digital post-press box-making solution.

- Box Factory: Finish all kinds of short-run/ scattered orders smoothly.

Because of its flexibility, the HD2508-U box making machine can easily adapt to changing business models, from traditional manufacturing to smart packaging and just-in-time production.

Conclusion

The HD2508-U Flexible Corrugated Carton Box Making Machine is not just an upgraded carton cutter — it’s a complete smart packaging solution.

By combining automation, precision, and flexibility, it helps manufacturers efficiently manage multiple short-run orders, cut down material waste, and reduce lead time.

In the era of customized and on-demand packaging, this digital system gives factories a powerful competitive edge — enabling them to deliver faster, smarter, and more efficiently than ever before.