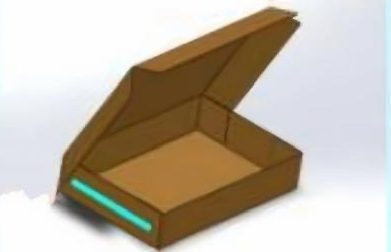

Carton Sealing Machine for Large-Size Packaging

Large cartons — often used in furniture, kitchen cabinets, and home appliances — present unique packaging challenges. Traditional tape sealing or manual labor often fails to deliver strong, consistent seals on oversized boxes. A hot melt glue carton sealing machine is specifically designed to handle extra-large cartons, ensuring secure, efficient, and cost-effective packaging. (Note: only suitable for side-sealed box M410)

The Challenges of Sealing Large Cartons

1. Labor Intensity

Oversized cartons are difficult to handle manually. Workers often need multiple people to fold, hold, and tape the flaps, which slows down packaging lines.

2. Inconsistent Sealing Quality

Tape often wrinkles, overlaps, or fails to fully secure the long flaps of wide cartons. Weak seals lead to open boxes during shipping, causing product damage or returns.

3. Material Waste

To compensate for weak adhesion, workers often apply multiple layers of tape, increasing material costs without guaranteeing durability.

How Carton Sealing Machines Solve These Issues

1. Wide Size Compatibility

The hot melt glue carton sealing machine can handle carton dimensions ranging from:

- Length: 300 – 2800 mm

- Width: 400 – 1200 mm

- Height: 36 – 300 mm

This wide size range makes it ideal for packaging wardrobes, cabinets, and large appliances.

2. Strong and Reliable Seals

Hot melt glue provides continuous bonding across long carton flaps. With options for single-line, double-line, or continuous spraying, the machine ensures strong seals even for cartons with corrugated board thickness from 2 – 7 mm.

3. Efficiency in Large-Scale Production

Instead of requiring multiple workers, the machine automates carton alignment, glue application, and pressing.

- Feeding speed: up to 40 m/min

- Glue spraying speed: up to 100 m/min

- Throughput: as high as 10 cartons per minute (when carton length is below 1200 mm)

This ensures both speed and consistency in furniture and appliance packaging.

4. Reduced Material and Energy Costs

Glue usage is controlled precisely:

- Single glue line: ~0.033 RMB per meter

- Double glue line: ~0.066 RMB per meter

Compared with multiple layers of tape, this offers substantial savings. At the same time, the 9.8 kW power system with servo controls ensures energy-efficient operation.

Industries That Benefit the Most

- Furniture Manufacturers – cabinets, wardrobes, and panel-based furniture.

- Home Appliance Producers – refrigerators, washing machines, and kitchen equipment.

- Export Packaging – where carton strength and appearance are critical for long-distance shipping.

Conclusion

For companies dealing with oversized cartons, switching from manual tape sealing to a hot melt glue carton sealing machine brings measurable improvements in cost savings, efficiency, and packaging quality. With carton size compatibility up to 2800 mm in length and 1200 mm in width, fast throughput of 10 cartons per minute, and precise glue application, these machines are a must-have for modern packaging lines.

Contact us today to learn how our carton sealing machines can handle your biggest packaging challenges.