Top 10 Questions About Multi-Blade Rip Saws — Answered by Experts

When woodworking factories consider upgrading their cutting equipment, one of the most common machines they hear about is the multi-blade rip saw. But what exactly does it do? How is it different from a regular saw? And is it really worth the investment?

To clear the confusion, we’ve gathered the 10 most frequently asked questions from furniture makers, flooring producers, and packaging factories — and answered them in detail.

1. What is a multi-blade rip saw?

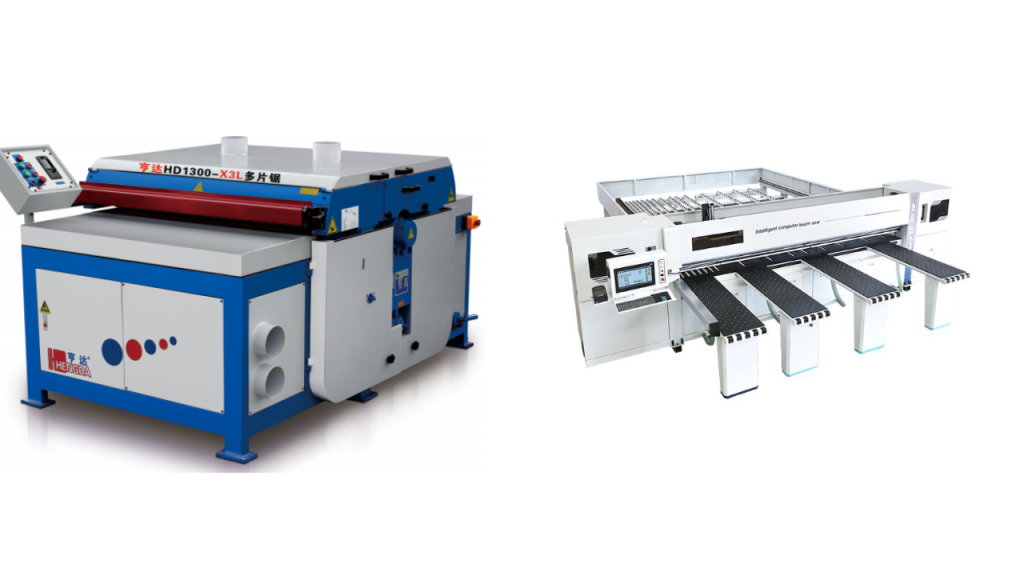

A multi-blade rip saw is an industrial woodworking machine designed to cut wide wood panels or planks into multiple smaller strips in just one pass. Unlike traditional cutting methods where each cut must be done separately, this machine is built with multiple circular saw blades mounted on a spindle, so it can process several cuts at once.

Think of it as the difference between slicing bread with one knife stroke per slice versus putting the whole loaf through a bread-slicing machine. The latter is faster, more consistent, and far less labor-intensive. That’s exactly what a multi-blade rip saw does for wood processing.

2. How is it different from a single-blade saw?

This is one of the biggest questions factory managers ask before making a purchase. A single-blade saw can certainly cut wood, but every cut requires a separate pass. If you’re cutting a 1.2-meter-wide plank into six pieces, that’s six passes — and six times the labor.

By contrast, a multi-blade rip saw makes all six cuts at the same time. The benefits are obvious:

- Fewer man-hours needed per order

- Higher cutting precision because all cuts are made in a single alignment

- Reduced material waste thanks to optimized spacing between blades

For a workshop with low daily output, a single-blade saw may still be acceptable. But for factories processing hundreds of boards every day, a multi-blade rip saw is almost always the smarter choice.

3. What industries use multi-blade rip saws?

The applications are surprisingly diverse. Here are a few of the most common industries that rely on these machines:

- Furniture factories: Cabinet doors, wardrobes, tabletops, and customized furniture components.

- Flooring production: Strips for hardwood or engineered flooring, where consistent size and clean edges are critical.

- Door and window frame manufacturers: Producing multiple rails or stiles in one pass saves huge amounts of time.

- Packaging industry: Wooden pallets, crates, and boxes often require repetitive cutting of panels into standard sizes.

In short, anywhere wood needs to be processed in large volume and with consistent sizing, multi-blade rip saws prove their worth.

4. What materials can it cut?

While designed primarily for solid wood, these machines are also suitable for a variety of wood-based materials. Depending on blade type and machine configuration, you can cut:

- Hardwoods like oak, walnut, teak, and mahogany

- Softwoods such as pine and fir

- Engineered boards including plywood, laminated boards, and blockboards

The key is to use the correct blade type and feed speed. With the right setup, even dense hardwoods can be cut efficiently without burning or splintering.

5. What are the size limitations?

Most standard multi-blade saws are designed to handle 1220mm × 2440mm panels, which are industry standard. However, many manufacturers also offer models with larger feed widths (up to 1300mm or more).

Thickness capacity is another factor. Some machines handle boards up to 60mm thick, while heavy-duty models can go even higher. When choosing a machine, it’s important to match the specs to your actual production needs. Overbuying a machine that’s too large for your daily operations only increases costs unnecessarily.

6. How does it improve production efficiency?

This is where multi-blade saws shine. By consolidating multiple passes into one, they:

- Save time: Operators can complete a day’s cutting workload in hours rather than days.

- Reduce labor dependency: Instead of three or four operators working on multiple saws, one or two workers can manage a single line.

- Improve precision: All strips cut from the same board will be exactly the same width, eliminating mismatched parts during assembly.

- Minimize waste: Proper blade spacing means fewer offcuts and higher material yield.

Factories that adopt multi-blade saws often report production increases of 2–3 times compared to traditional methods, without expanding labor.

7. Is it difficult to operate?

This is a concern for many smaller factories. Fortunately, modern machines are designed to be operator-friendly. Key features include:

- Automatic feeding rollers that guide the material smoothly without manual pushing.

- Intuitive control panels that allow quick adjustments of blade spacing and feed speed.

- Protective covers and guards to reduce operator exposure to moving blades.

With just a few days of training, most workers can operate a multi-blade saw confidently. For factories with high turnover, this ease of use is a major advantage.

8. What about safety?

Safety is always a priority. Compared to traditional open saws, multi-blade rip saws are much safer because:

- Blades are enclosed within the machine housing.

- Emergency stop systems cut power instantly if needed.

- Feeding systems keep the operator’s hands away from cutting blades.

Still, operators must follow strict protocols: no loose clothing, no manual interference while the machine is running, and always using protective eyewear and ear protection.

9. How do I maintain a multi-blade rip saw?

Regular maintenance is the secret to long-term reliability. A good routine includes:

- Daily cleaning: Remove sawdust, resin, and debris at the end of each shift.

- Blade care: Inspect for dullness or cracks, sharpen regularly, and replace if damaged.

- Lubrication: Apply oil or grease to moving parts like rollers and bearings.

- Calibration checks: Ensure blades and feed rollers remain properly aligned to prevent uneven cuts.

By keeping up with basic maintenance, you can extend the lifespan of your saw by years and avoid costly downtime.

10. How do I choose the right model for my factory?

This is often the final — and most important — question. The answer depends on several factors:

- Production volume: Are you processing a few dozen boards a day, or hundreds?

- Material type: Hardwoods require sturdier, more powerful models.

- Cutting flexibility: Some models feature dual spindles for simultaneous cutting and grooving, while simpler models focus on basic ripping.

- Budget vs. ROI: While the initial investment may seem high, calculating the savings in labor, time, and material waste often proves the machine pays for itself quickly.

For many businesses, the best approach is to discuss needs directly with the manufacturer or supplier. They can recommend a configuration that balances capacity, cost, and growth potential.

Conclusion

The multi-blade rip saw is more than just another woodworking tool — it’s a gateway to higher productivity, safer operations, and more consistent product quality. By understanding these top questions, factory managers and decision-makers can make an informed choice that fits both current workloads and long-term business growth.

If you’re considering upgrading your cutting equipment, it’s worth asking: how much more could your factory produce if cutting time was reduced by half — or even more?