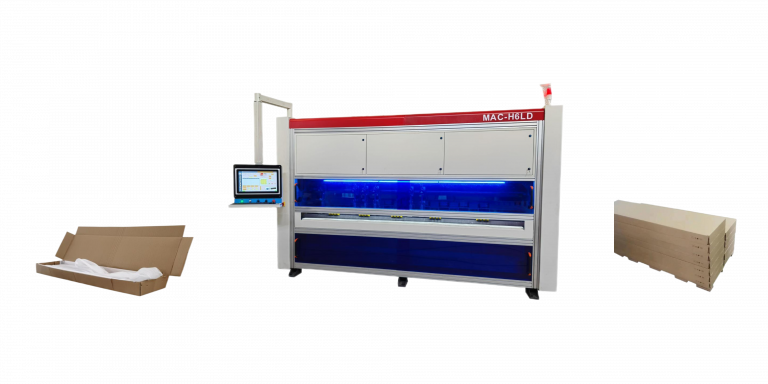

How a Corrugated Cardboard Box Cutting Machine Saves Packaging Costs for Furniture Manufacturers

In the furniture industry, packaging is not just about protection—it’s also about cost. With products of varying sizes such as wardrobes, cabinets, and tables, it’s challenging to manage carton procurement, storage, and waste. This is where a corrugated cardboard box cutting machine becomes a powerful solution. By producing cartons on demand, factories can significantly cut costs and improve efficiency.

The Hidden Costs of Traditional Carton Procurement

Before adopting a corrugated cardboard box cutting machine, many factories rely on purchasing cartons in bulk. This approach creates several hidden expenses:

1. High Inventory Costs

Factories need cartons of different sizes to match diverse furniture products. This requires purchasing multiple types of cartons in advance. Storing them takes up warehouse space, which could otherwise be used for raw materials or finished goods. For large factories, carton inventory alone can occupy hundreds of square meters, leading to additional rent, lighting, and management expenses.

2. Cash Flow Pressure

Buying cartons in bulk ties up working capital. Instead of using funds for production improvements or new machinery, a significant amount of money sits in carton stock, which may not even be used immediately.

3. Waste from Oversized Cartons

When the correct carton size is unavailable, factories often use a larger carton and fill the empty space with foam or paper. This not only wastes packaging materials but also increases shipping costs because larger cartons take up more space in trucks or containers.

4. Limited Flexibility and Delays

Furniture designs change constantly. A newly developed wardrobe or customized cabinet may not fit any existing carton sizes. Factories then face two options: order new cartons and wait for delivery, or risk packaging products in unsuitable boxes. Both options reduce efficiency and may delay shipments.

5. Environmental Impact

Over-purchasing and excessive filler materials generate more packaging waste. For factories looking to meet sustainability goals or attract eco-conscious customers, this is a long-term disadvantage.

How a Corrugated Cardboard Box Cutting Machine Reduces Costs

Adopting a corrugated cardboard box cutting machine directly addresses these hidden costs and transforms packaging operations.

1. On-Demand Carton Production

Instead of stockpiling dozens of carton sizes, factories can produce cartons instantly based on product dimensions. Whether packaging a small bedside table or a large wardrobe, the right-sized carton can be produced within minutes. This reduces the need for carton inventory by up to 70%, freeing valuable warehouse space.

2. Reduced Cardboard Waste

The corrugated cardboard box cutting machine uses precision cutting technology to optimize material usage. Each carton is designed digitally to fit the product perfectly, minimizing excess cardboard. Factories typically report a 20–30% reduction in raw material waste, which translates directly into cost savings.

3. Lower Labor and Handling Expenses

Without the machine, workers spend time locating the right carton, modifying it, or adding filler. With the machine, cartons are cut and folded in real time, reducing manual handling. Packaging teams become more efficient, and fewer workers are required for the same workload.

4. Improved Shipping Efficiency

Right-sized cartons reduce shipping volume. For example, if oversized cartons take up 15% more truck space, switching to on-demand cartons allows the same truck to carry more products. This reduces logistics costs and lowers the carbon footprint of transportation.

5. Stronger Customer Experience

Customers receiving perfectly sized cartons perceive the brand as more professional. In addition, less filler material means easier unboxing, which is increasingly valued in the e-commerce and furniture markets.

Case Example: A Furniture Factory’s Cost Savings

A furniture manufacturer producing wardrobes, shelves, and kitchen cabinets in Sichuan, China faced challenges with carton inventory and waste. After investing in a corrugated cardboard box cutting machine, they achieved:

- 30% reduction in packaging costs within the first year

- 60% less storage space required for cartons

- Faster packaging process, improving delivery times

The investment paid for itself in less than 18 months.

Conclusion

For furniture manufacturers, packaging can be a hidden drain on profits. A corrugated cardboard box cutting machine offers a smarter way to control costs by reducing waste, minimizing storage needs, and streamlining logistics.

Instead of managing hundreds of pre-purchased cartons, factories gain the flexibility to produce boxes on demand—perfectly sized for each piece of furniture. This not only lowers packaging expenses but also improves efficiency and customer satisfaction.

In a competitive market where every percentage of cost savings matters, adopting a corrugated cardboard box cutting machine is not just an equipment upgrade—it’s a long-term investment in profitability.