How a Furniture Manufacturer Boosted Output with Box Maker Machine

Three years ago, a mid-sized furniture manufacturer based in Poland was growing steadily—but behind the scenes, their packaging process was holding them back. Then they came to us for a packaging solution.

Before, they shipped hundreds of sofas, wardrobes, and coffee tables every month. But preparing the shipping cartons was slow, wasteful, and inconsistent. Their workers manually cut cardboard, often leading to imprecise box sizes, excessive material waste, and frequent rework.

What they needed was a flexible, automated solution that could keep pace with production—and ensure every piece of furniture was protected in a perfectly-sized box.

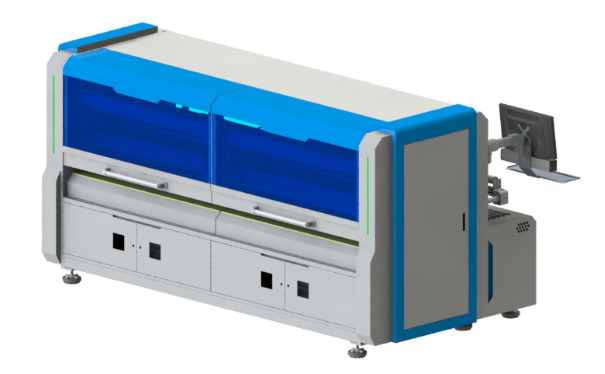

The Solution: Misunda’s MAC-H6LD Box Maker Machine

After evaluating several options, the manufacturer chose the MAC-H6LD model from Misunda—a high-speed, multi-silo, fully automatic box maker machine.

The MAC-H6LD stood out for its:

- Support for up to 12 paper silos – Ideal for complex size ranges and multiple cardboard sizes

- Cutting + slotting + creasing in one pass – Full box blank output

- Touchscreen control with real-time box switching

- Dust-free circular blade cutting system – Clean edges, minimal maintenance

- Maximum working width of 2500mm, covering all their packaging sizes

Implementation & Workflow Integration

The MAC-H6LD was installed near the end of their production line. It was configured to receive corrugated sheets directly from the warehouse and automatically generate box blanks as per the day’s furniture batch list.

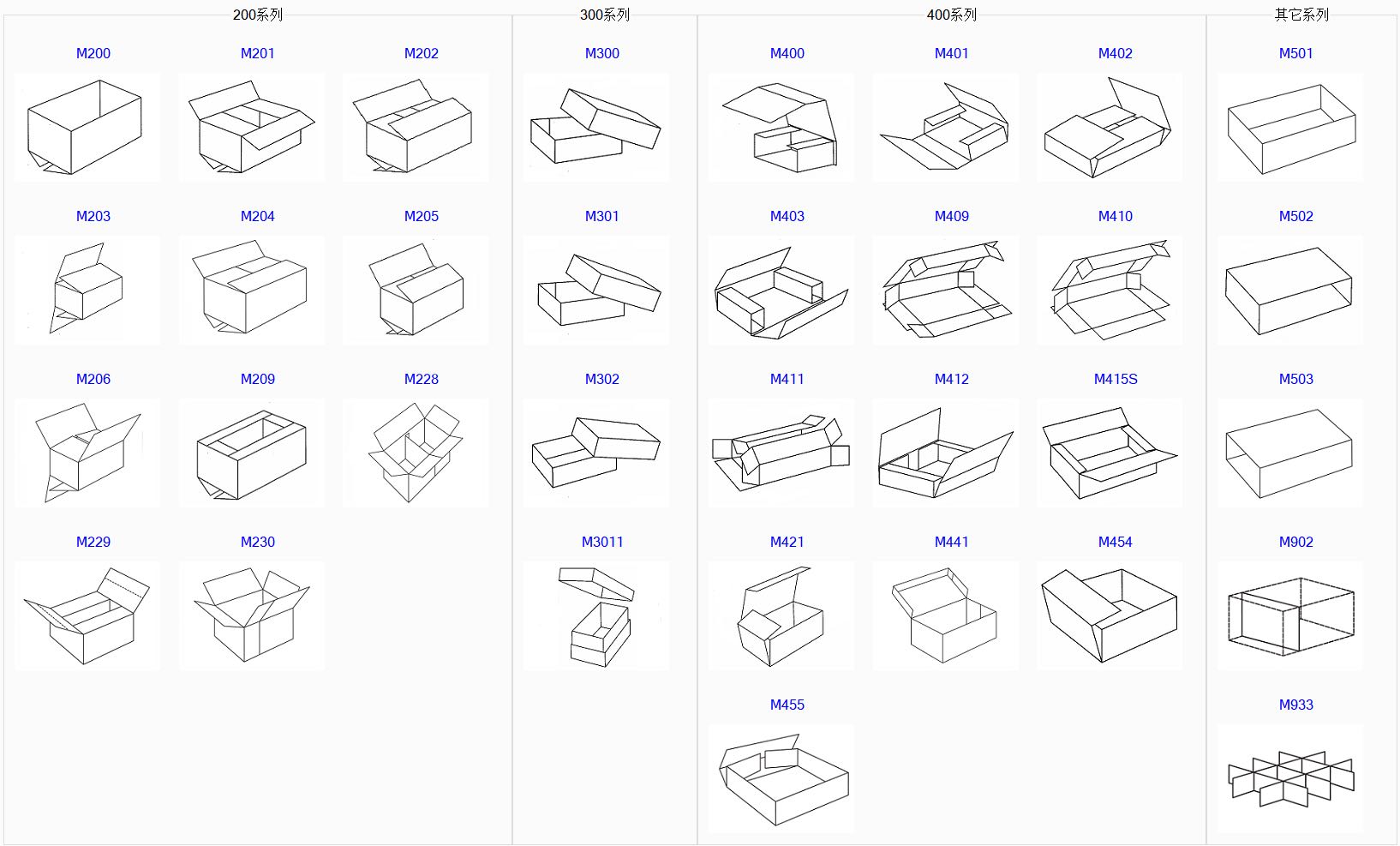

Box types included

- Double wall boxes for small items

- Triple wall cartons for heavier furniture like wardrobes

- Fivefold wall boxes for export products

Integration highlights

- Input the size data directly and insert the USB or excel files

- Operators trained in just a half day

- Real-time switching between up to 30+ preset box types

Results After 3 Months

| Metric | Before | After MAC-H6LD |

|---|---|---|

| Average boxes/day | ~350 | 750+ |

| Scrap rate | ~15% | <4% |

| Box prep labor | 5 workers | 1 workers |

| Downtime from packaging errors | Frequent | Rare |

| Lead time for new box sizes | ~30 minutes | <5 minutes |

In short, the MAC-H6LD more than doubled packaging output, while cutting labor and material costs significantly.

What the Customer Said

“We never imagined that packaging could be automated this precisely. The MAC-H6LD not only keeps up—it outpaces our furniture line. We’re saving time, money, and cardboard every day.”

— Production Manager, Furniture Manufacturer

“Before, our team was constantly fixing packaging issues—wrong box sizes, torn edges, misaligned creases. It was frustrating. Now, everything just works. We input the product dimensions, and the machine delivers perfect blanks, every time.”

— Packaging Supervisor

“One of our biggest concerns was training. We assumed it would take weeks to get our staff comfortable with the system. But honestly, after just one day, they were already confident. The touchscreen interface is intuitive, and job switching is as easy as selecting from a preset menu.”

— Factory Operations Director

Conclusion: Scalable Box Production for Growing Brands

As product variety increases and customer expectations rise, having the right packaging machinery is no longer optional. With Misunda’s MAC-H6LD, the furniture factory turned a packaging bottleneck into a competitive edge.

If you’re dealing with inconsistent box sizes, wasted cardboard, or packaging delays, it may be time to upgrade.