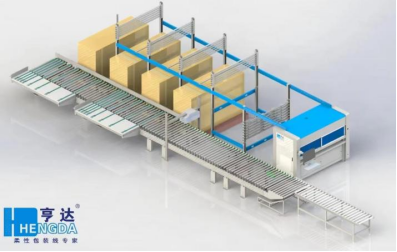

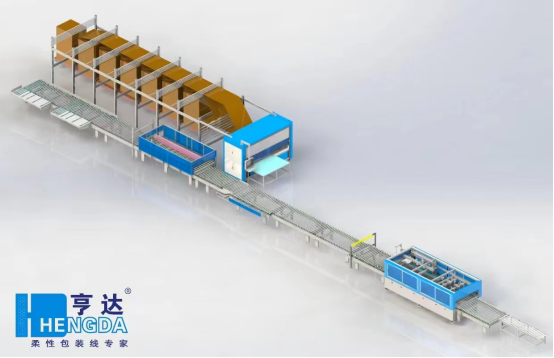

Hengda Intelligent Packaging Line: Precision Size Measurement Station

In highly automated packaging production lines, accurate dimensional measurement is the critical first step to ensure smooth subsequent processes like cutting, folding, and sealing, ultimately guaranteeing final packaging quality. Hengda’s intelligent packaging line features advanced size measurement station that provides “precision vision” for the entire packaging process, ensuring flawless data collection from the source.

Core Value of Measurement Station

In corrugated carton packaging production line, even minor dimensional deviations can cause inefficiencies, material waste, or product damage. Precise size measurement data serves as:

- The foundation for intelligent cutting

- The basis for optimized material utilization

- The key to automated production efficiency

- The guarantee of final product quality

Hengda Measurement Station Series: Diverse Solutions

We offers multiple technical solutions to accommodate different workpiece types and measurement needs:

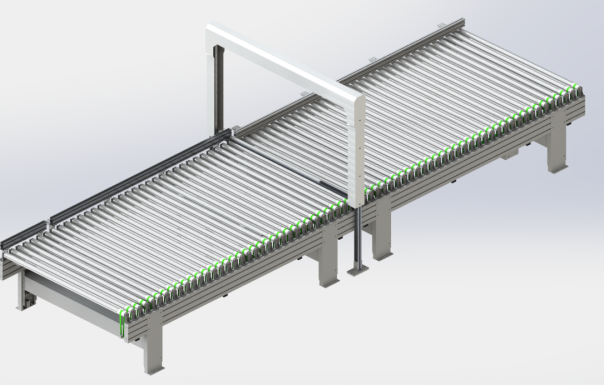

MP-SJC Intelligent Precision Measurement Station

- Single-station design with synchronous length/width measurement

- Accuracy: ±1mm

- Speed: 3-4 packages/minute

- Maximum dimensions: 2800×1200×250mm

- Minimum dimensions: 300×300×18mm

MP-SJCG Intelligent Light Curtain Measurement Station

- Non-contact measurement using infrared light curtains

- Accuracy: ±2.5mm

- Speed: 8-12 packages/minute

- Maximum dimensions: 2800×1200×300mm

- Minimum dimensions: 300×300×18mm

- Applicability note: Compared with the other two models, MP-SJCG is slightly lower in accuracy, so it is not as suitable as the other two models for the packing measurement of panel furniture, and is more suitable for the scenarios where the requirements for dimensional accuracy are relatively loose or where the pursuit of very high measuring speed is required.

MP-SJCL Length/Width Synchronous Measurement Station

- Dual-station design with separate length/width measurement

- Accuracy: ±1mm

- Speed: 4-6 packages/minute

- Maximum dimensions: 2800×1200×250mm

- Minimum dimensions: 300×300×18mm

How Size Measurement Stations Empower Intelligent Packaging

Our size measurement stations are essential components of its intelligent carton production line. The collected data directly guides:

- Intelligent carton cutters to produce precisely matched boxes

- Flipping and folding machines for accurate operations

- Carton sealers for smoother, more secure sealing

By providing accurate dimensional input, our intelligent packaging line achieves fully automated, intelligent management from raw materials to finished packaging, minimizing human error and resource waste while delivering exceptional production efficiency and packaging quality.

Choosing Hengda packaging line means establishing the most solid and precise foundation for your intelligent packaging process.