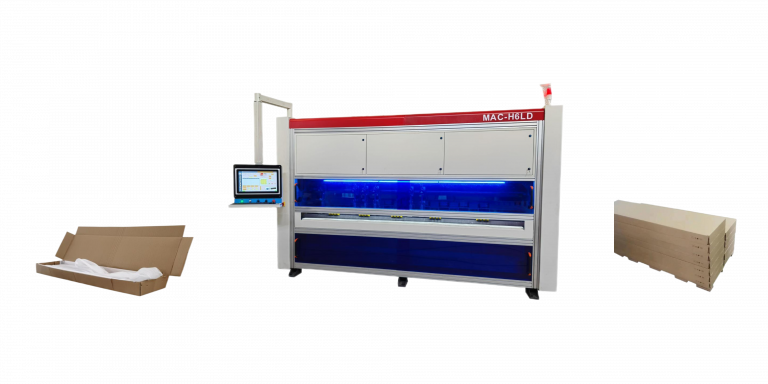

Intelligent Corrugated Carton Cutting Machine For Cost Efficiency & Productivity Excellence

As a flexible packaging line expert, Hengda intelligent corrugated carton cutting machine delivers more than advanced cutting equipment—it provides integrated solutions that optimize material costs, boost productivity, and ensure premium quality. This analysis reveals how Hengda’s smart packaging systems create tangible business value.

Smart Corrugated Board Selection for Material Cost Optimization

| Corrugated Type | Price (approx.) | Key Advantage |

|---|---|---|

| A8A (2-ply) | ¥2.3/m² | Budget option |

| A8A (Continuous 3-ply) | ¥2.68/m² | 18% faster processing |

| A=A (5-ply) | ¥3.3/m² | Heavy-duty protection |

| A=A (Continuous 3-ply) | ¥3.8/m² | 25% less material waste |

Our carton machine is designed to handle continuous board (z-fold cardboard), which means the machine can automate feeding from large rolls or stacks without interruption. This seamless feeding dramatically reduces manual intervention, changeover time and material handling costs. Combined with the machine’s built-in intelligent nesting algorithms, the carton machine is able to handle multiple sizes of cardboard and choose the most suitable one for each package to maximize board utilization and minimize trim waste, resulting in more qualified cartons with less raw material. From a holistic perspective, the combination of continuous board and our carton machines can effectively offset or even surpass their apparent price disadvantage, realizing better overall material cost effectiveness.

Key Insight: While continuous corrugated boards cost 15% more upfront, their compatibility with our automated packaging systems reduces changeover time by 30% and improves material utilization through intelligent nesting algorithms.

Automation vs Manual Packaging

Our automated cutting systems deliver transformative efficiency gains:

| Comparison Item | Manual Packaging | Automated Packaging (Cutting Machine) | Improvement Effect |

|---|---|---|---|

| Working Hours | 11 hrs/day per person | 11 hrs/day | – |

| Daily Unfolded Area | 165m²/day | 320m²/day | ~94% |

| Daily Packaged Items | ~110 packages | ~200 packages | ~82% |

Conclusion: automated packaging nearly doubles daily production capacity while achieving about 25% material savings.

Core Advantages of Our Packaging Machine

Diversification and Time Savings:

- Supports multi-specification cutting and quick switching

- Compatible with FEFCO international standard box types and custom requirements

- Significantly reduces production preparation time

Carton Quality Assurance and Logistics Optimization:

- Ensures precise dimensions (±1mm) and neat edges

- Reduces product damage during transportation

- Optimizes sealing and stacking efficiency

Conclusion

HENGDA intelligent corrugated carton cutting machine is a comprehensive solution that delivers significant economic benefits. Through intelligent material management, automated production efficiency, and strict quality assurance of finished products, it helps enterprises achieve cost control and efficiency improvement.