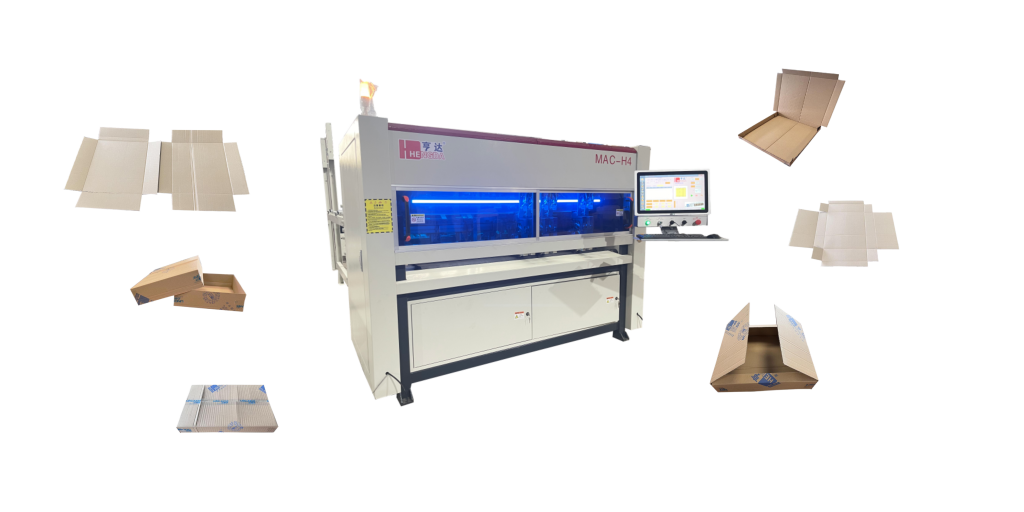

Hengda Corrugated Cardboard Box Machine: Small With Big Capabilities

In customized corrugated carton production, balancing equipment costs while flexibly meeting cutting requirements for cartons of varying widths is a common challenge. Hengda’s intelligent corrugated cardboard box machine addresses this dilemma ingeniously with its unique horizontal/vertical discharge switching mechanism, enabling “small” machines to deliver “big” performance.

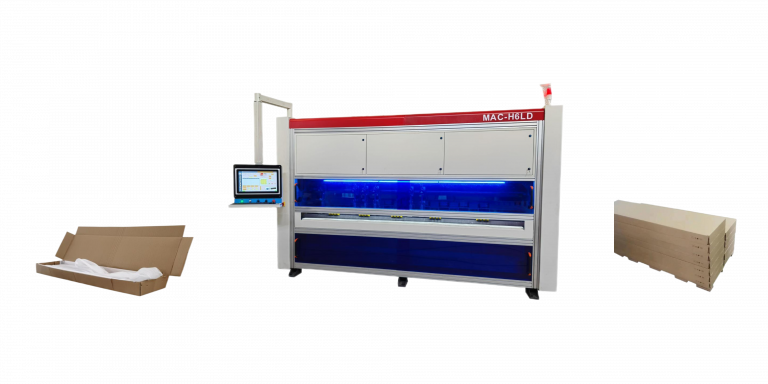

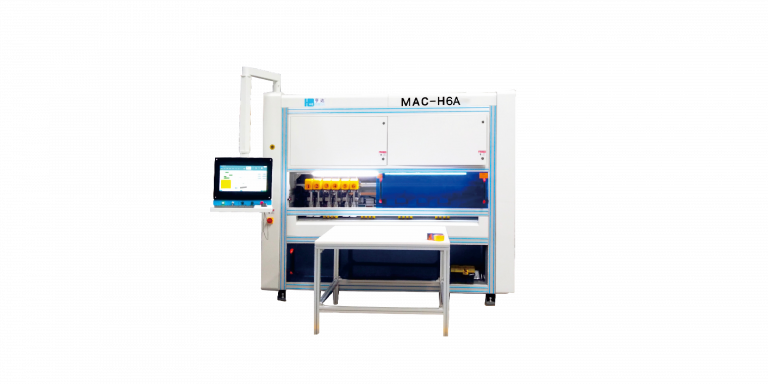

Width Options: Choosing Between 1600mm and 2500mm Width Machine

We offers two primary machine widths: 1600mm and 2500mm. While 2500mm machines theoretically handle wider boards and larger carton sizes, investing in extra-wide equipment for occasional wide-carton needs may impose unnecessary costs for factories primarily producing standard-sized cartons.

Smart System: Horizontal-First, Vertical-Assist

To optimize cost-efficiency and flexibility, our corrugated cardboard box machine feature automatic horizontal/vertical discharge switching:

- Horizontal Discharge (Default): The machine prioritizes horizontal cutting, aligning carton layouts with the board’s width for optimal precision and downstream processing efficiency.

- Intelligent Vertical Switching: When a carton’s unfolded width exceeds the board’s limit, the system auto-detects and switches to vertical discharge, aligning the layout with the board’s length to cut wider cartons on narrower machines.

The Math Behind Horizontal/Vertical Switching

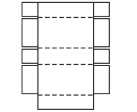

Take a 1600mm cardboard box machine as an example: How does it determine when to trigger vertical discharge? The logic lies in carton unfolding dimensions.

For an FEFCO M410 carton, the unfolded width formula is roughly 2W + 3H (simplified).

Scenario: Packaging stacked furniture panels (each ~18mm thick). A carton wrapping 3–4 panels would have a height (H) of ~66mm.

Calculation for 1600mm Board:

- Carton max width: 2W + 3H ≤ 1600mm

- With H = 66mm: 2W + (3 × 66mm) = 1600mm → W ≈ 701mm

Result: If the M410 carton’s width (W) exceeds ~700mm, the 1600mm cardboard box machine auto-switches to vertical discharge, enabling “small” machines to cut oversized cartons.

Strategic Advantage: Low Investment, High Returns

This design caters to factories needing occasional wide cartons, allowing them to:

- Choose cost-effective 1600mm corrugated cardboard box machine instead of pricier 2500mm models.

- Reduce upfront costs while maintaining flexibility.

Trade-offs with Vertical Discharge

While versatile, vertical discharge has considerations:

- Folding/Stability: Cartons cut vertically may exhibit slight differences in fold integrity.

- Downstream Compatibility: Automated processes (e.g., auto-sealing) may require adjustments for vertically discharged cartons.

Conclusion

HENGDA’s intelligent discharge-switching technology exemplifies its commitment to cost-smart, adaptable solutions. By harmonizing performance and affordability, it empowers businesses to meet diverse packaging needs without over-investment. When selecting equipment, weighing these smart features against your workflow ensures the optimal choice.