Corrugated Cardboard Carton Cutting Machine Model Guide

As more and more factories opt for carton cutting machines to achieve efficiency and cost reduction, selecting a corrugated cardboard carton cutting machine that perfectly matches your production scale and requirements is crucial. Hengda, as a flexible packaging line expert, understands the diverse challenges faced by different factories and has developed a comprehensive range of carton machine models—from entry-level to high-performance options. This article provides a detailed analysis of Hengda’s main corrugated cardboard carton cutting machine models to help you make a precise match and optimize your investment.

Key Considerations When Choosing a Corrugated Cardboard Carton Cutting Machine

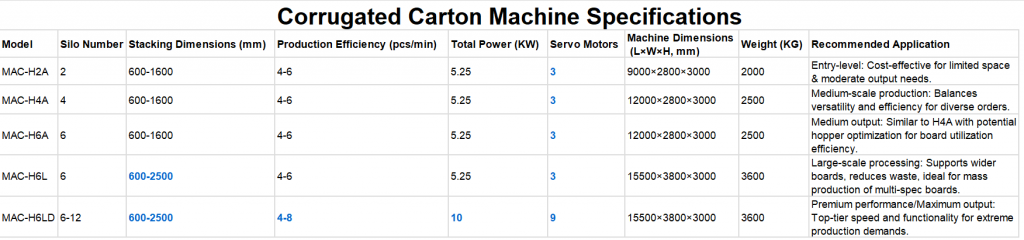

When selecting the right corrugated cardboard carton cutting machine, we should focus on the following core parameters:

- Production Efficiency: Directly impacts carton output per unit time.

- Corrugated Board Stacking Specifications & Processing Range: Determines the maximum/minimum carton sizes and material widths the machine can handle.

- Rated Total Power: Reflects energy consumption levels.

- Machine Dimensions & Weight: Affects installation space and floor load capacity.

- Original Paper Stacking Quantity: Influences the number of paper stacks loaded at once and frequency of paper changes.

Detailed Analysis of Corrugated Cardboard Carton Cuuting Machine Models

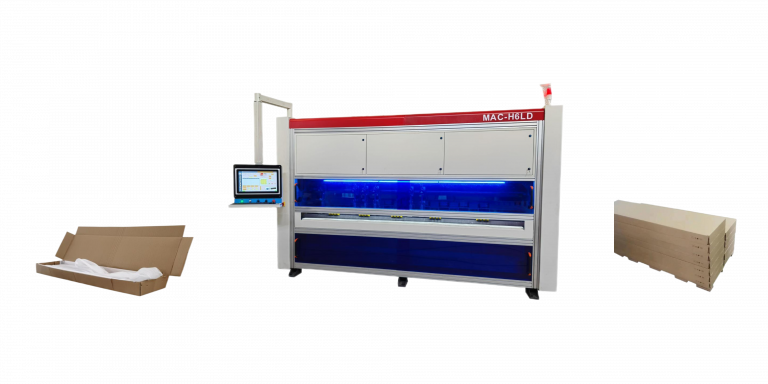

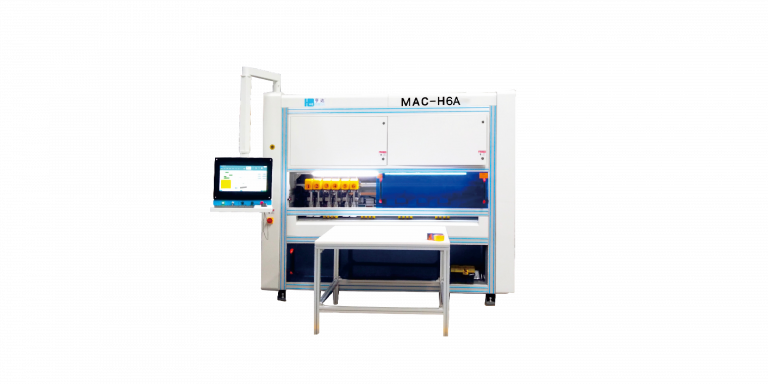

Our carton machine series includes five main configurations: MAC-H2A, MAC-H4A, MAC-H6A, MAC-H6L, and MAC-H6LD, each designed to meet specific production demands.

How to Choose the Right Model?

- Assess Your Daily/Monthly Production Needs

- For moderate output: MAC-H2A, MAC-H4A(cost-effective).

- For high cardboard utilization: MAC-H6A(material saving).

- For high-volume, rapid turnaround: MAC-H6LD (peak efficiency in the series).

- Evaluate Your Typical Carton Sizes (there’re something need to be considered)

- Standard cartons (≤1600mm layout width): MAC-H2A/H4A/H6A.

- Extra-wide boards (up to 2500mm layout width) : MAC-H6L/H6LD.

- Consider Workspace and Power Supply

- Compact footprint: MAC-H2A (ideal for space-constrained facilities).

- Balanced performance: MAC-H4A (supports multi-paper stacking for material savings).

- Heavy-duty requirements: MAC-H6LD (needs larger space and 10kW power).

- Material Type and Stacking Efficiency

- All models support single/double-wall corrugated board or roll paper.

- MAC-H6L/H6LD allow more paper stacks, reducing changeover frequency for continuous large-scale production.

Our Unwavering Advantages

Regardless of the model, all of our carton machine share core superior technologies:

- Patented Cutting System: Disk-style flat knives with constant-gap fracture cutting ensure dust-free, smooth, burr-free precision and extended tool life.

- Multi-Carton Tyoes Compatibility: Supports multiple kinds of FEFCO-standard cartons.

- Smart Data Processing: Multiple input methods (manual, Excel, ERP/MES integration) for precise sizing and efficient production management.

Conclusion

Choosing a our corrugated cardboard carton cutting machine isn’t just purchasing an equipment—it’s investing in an efficient, flexible, and future-ready smart packaging solution. By analyzing your production needs alongside our model specifications, you’ll select the ideal “tool” to streamline processes and boost competitiveness.

Upgrade your packaging line with HENGDA—where precision meets productivity.