Engineering Advantages of Hengda Multi-Blade Saw Spindle

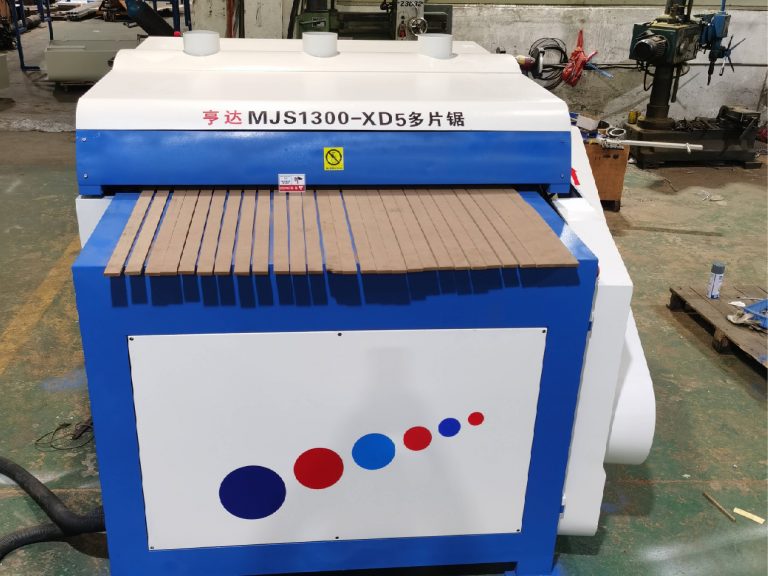

The spindle of a multi-blade saw is a critical core component that determines cutting precision and overall machine stability. Its quality and processing techniques directly impact the long-term performance of the equipment. Hengda equips all its multi-blade saws with spindles that undergo specialized hardening and tempering treatments, as well as precision dynamic balancing tests. This article details how these engineering refinements enhance the performance of multi-blade saws.

Function and Challenges of the Spindle

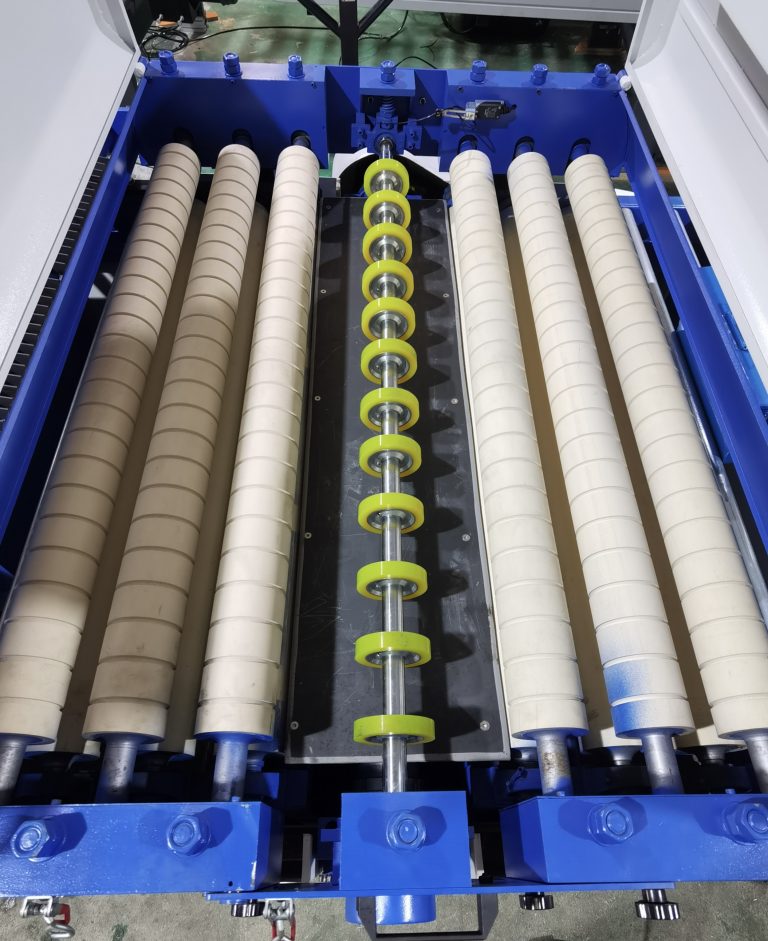

The spindle in a multi-blade saw is responsible for securing and driving multiple saw blades at high speeds. During wood cutting, it must withstand tremendous rotational forces, cutting resistance, heat, and continuous vibration. Any imperfection in the spindle directly affects cutting accuracy, surface finish quality, blade lifespan, overall machine durability, and operational noise levels.

Material and Heat Treatment of the Spindles

Our spindles are crafted from high-quality alloy steel. To optimize performance, each spindle undergoes the following heat treatments:

- Hardening Treatment: This process increases the surface or overall hardness of the material. The hardened spindle exhibits significantly improved wear resistance, enabling it to withstand high-speed friction and wood chip abrasion over prolonged use without premature wear.

- Tempering Treatment: Following hardening, the spindle undergoes tempering. By heating the material to a specific temperature and controlling the cooling rate, this process enhances toughness while retaining high hardness. The improved toughness prevents brittle fractures under unexpected impacts or heavy loads, ensuring greater durability and operational safety.

The combination of hardening and tempering gives the spindles both high hardness and superior toughness, allowing them to endure long-term, high-intensity workloads while maintaining structural integrity.

Dynamic Balancing of the Spindle

Imbalances in rotating components can cause vibration at high speeds. In a multi-blade saw spindle, such imbalances lead to several performance issues:

- Increased machine vibration and elevated noise levels.

- Accelerated fatigue and wear on saw blades, shortening their lifespan.

- Degraded cut quality, resulting in rough or uneven surfaces.

- Premature wear on other machine components, particularly bearings, due to excessive vibration.

To address these issues, every Hengda spindle undergoes rigorous precision dynamic balancing tests and adjustments. Using professional balancing equipment, we precisely measure and correct any imbalances during high-speed rotation.

Benefits of Dynamic Balancing Include:

- Reduced Vibration: Ensures minimal vibration during high-speed operation, enhancing machine stability and significantly lowering noise.

- Extended Blade Life: Minimizes vibration-induced fatigue and wear on blades, reducing consumable costs.

- Guaranteed Cutting Precision: A stable spindle is the foundation for high-precision cuts, ensuring consistent and smooth cutting surfaces.

Summary of Performance Advantages

The design and manufacturing processes of our multi-blade saw spindles deliver several notable benefits:

- Exceptional Durability: Hardened and tempered spindles resist wear and deformation, ensuring long-term stable operation.

- Superior Stability: Precision dynamic balancing minimizes vibration, optimizing machine performance.

- Enhanced Cutting Precision: Stable spindle rotation guarantees consistent and accurate cuts.

- Extended Consumable Life: Reduced vibration prolongs blade lifespan.

- Improved Working Environment: Significantly lowers operational vibration and noise levels.

Conclusion

The material selection, heat treatment, and dynamic balancing of the spindle are key indicators of a multi-blade saw’s manufacturing quality. Hengda’s commitment to these engineering details reflects our dedication to product performance and customer value. Choosing our multi-blade saws means investing in equipment that delivers stable, precise, efficient, and long-lasting cutting performance.