Multi Blade Rip Saw vs. CNC Panel Saw: Choosing the Right Cutting Solution

Many of us have confusions about the differences between multi-blade rip saw machine and CNC panel saw machine. Both machines excel in different areas. This article walks you through their core differences, strengths, and ideal use cases so you can select the best fit for your operation.

Cutting Mechanics: Blade-Fixed vs. Board-Fixed

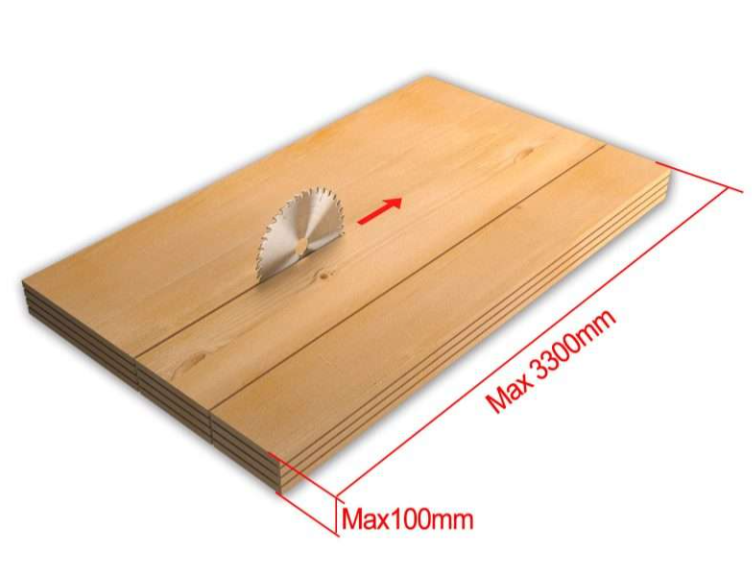

Multi-Blade Rip Saw

- Blade Fixed, Board Moves: Multiple saw blades are mounted side-by-side on a single arbor. A powered conveyor pushes boards through the blades in one continuous pass.

- Single-Board Operation: Stacking panels is unsafe and impractical. These machines are optimized for feeding one sheet at a time.

CNC Panel Saw

- Board Fixed, Blade Moves: The wood panel is clamped to a stationary table, and a motorized saw head (or gantry) travels along X–Y axes to make each cut.

- Stack Cutting: You can safely stack multiple panels (commonly 2–4 high) and cut them simultaneously—perfect for cutting identical parts in small batches.

Precision & Repeatability

- Multi Blade Rip Saw:

- Achieves ±0.2 mm width tolerances across high-speed ripping.

- Ideal for consistent, parallel strips (e.g., flooring planks, door stiles).

- CNC Panel Saw:

- Delivers ±0.1 mm or better positional accuracy.

- Handles complex geometries—straight cuts, miters, dados, and angled profiles—with computerized repeatability.

Production Throughput

- Multi Blade Rip Saw:

- Have an advantage at high throughput for long, straight rip cuts.

- Best for operations needing thousands of linear meters of strip per shift.

- CNC Panel Saw:

- Slower throughput per part due to individual head movements and indexing.

- Excels when cutting a variety of shapes or nesting many parts from large sheets.

Material Yield & Waste Reduction

- Multi Blade Rip Saw:

- Optimizes parallel rip layouts, keeping waste under 5% for uniform-width parts.

- About 4 times more efficient than CNC panel saw machine when cutting wood panel into strips.

- CNC Panel Saw:

- Uses automated nesting software to arrange parts and minimize offcuts across the entire sheet.

- Ideal for small-batch, multi-part cutting where material optimization matters most.

Automation & Flexibility

- Multi Blade Rip Saw:

- Can integrate into production line with automated feeding systems with infeed/outfeed devices.

- Advanced model with quick-swap shafts (e.g., Hengda HDZ1300) allow rapid blade-set changes for different strip widths automatically.

- CNC Panel Saw:

- Fully programmable cut patterns via CNC—no manual spacing changes required.

- Can perform grooving, bevel cuts, and custom profiles in a single setup.

Cost, Footprint & ROI

| Aspect | Multi Blade Rip Saw | CNC Panel Saw |

|---|---|---|

| Equipment Cost | Low~moderate | High |

| Footprint | Compact | Larger |

| Labor Requirement | Low (one operator) | Moderate (programming + setup) |

| ROI Break-Even | Often 4-7 months for high-volume | 12–24 months, depending on volume |

Ideal Applications

- Multi Blade Rip Saw

- Flooring plank and strip production

- Door frame stiles, jambs, and pocket lining

- Pallet slats, crate components

- CNC Panel Saw

- Cabinet door panels, furniture parts

- Nested small parts from whole sheets

- Decorative moldings, dados, and angled cuts

Making Your Choice

- High-Volume, Straight Cuts → Multi Blade Rip Saw

- Multi-Part, Complex Shapes, Stacked Panels → CNC Panel Saw

- Mixed Production → Combine both: use a gang rip for rip-heavy tasks and a CNC saw for profiling and nesting.

Conclusion

Both multi blade rip saws and CNC panel saws have distinct advantages. By understanding their cutting mechanics, precision levels, throughput capabilities, and ideal use cases, you can align your equipment investment with your production needs—ensuring the right balance of speed, accuracy, and material yield.

Ready to optimize your production?

Contact us for a personalized consultation!

Web: www.misunda.com

Tel: +86-13702963227