Top Applications of Wood Plate Multi Blade Rip Saw Machines in Furniture and Flooring Industries

Discover how wood plate multi blade rip saw machines transform furniture and flooring production with precision, speed, and material efficiency.

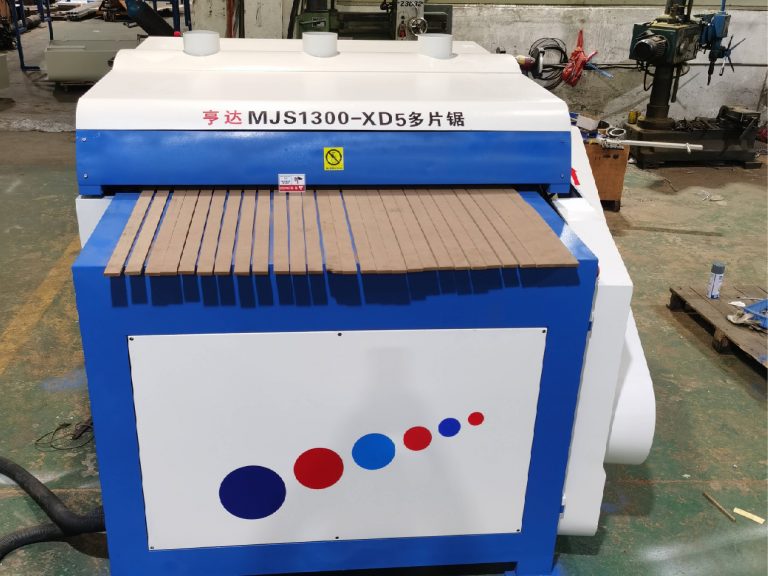

The wood plate multi blade rip saw machine has become a vital tool in modern manufacturing, offering unparalleled efficiency and precision.

From high-volume furniture production to premium flooring manufacturing, these machines deliver consistent results across a range of materials and applications.

This article explores the top industries and product types that benefit from adopting a wood plate multi blade rip saw machine, revealing why it is a smart investment for today’s competitive manufacturing landscape.

Panel Furniture Manufacturing

Panel furniture production demands high precision and fast throughput — two areas where the wood plate multi blade rip saw machine excels.

Optimized for Mass Production

In the manufacturing of cabinets, wardrobes, bookcases, and office desks, panels must be cut accurately and efficiently. A multi blade rip saw allows manufacturers to cut multiple strips in a single pass, dramatically increasing daily output without sacrificing dimensional accuracy. This not only improves productivity but also helps minimize material waste, a key concern in competitive markets.

Consistent Quality Across Batches

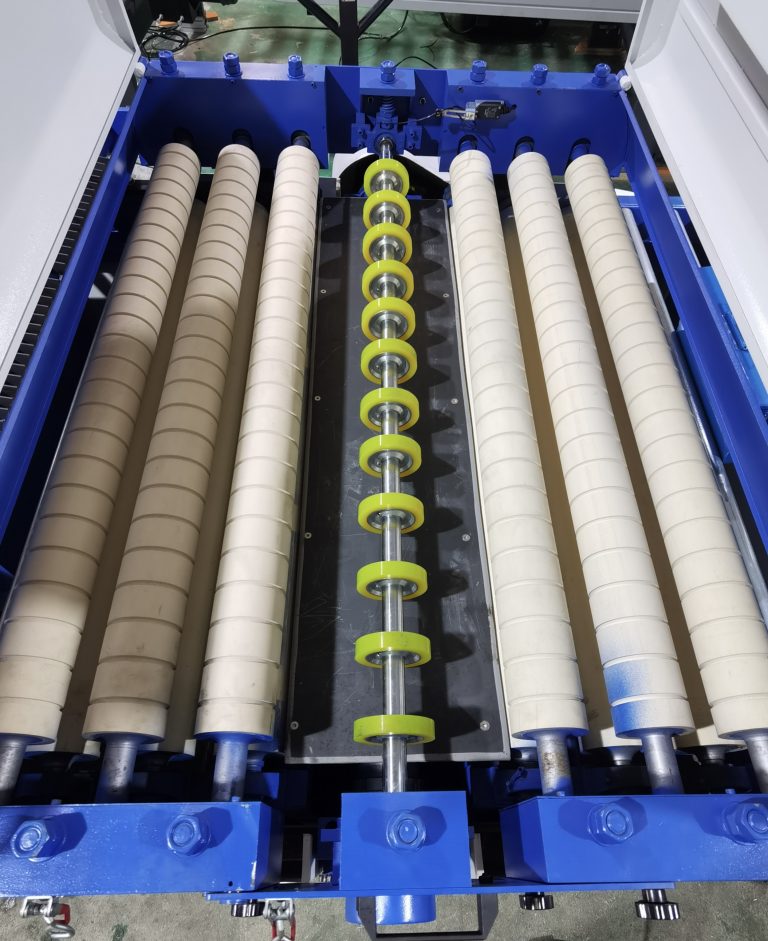

With servo-controlled blade adjustment and industrial-grade stability, wood plate multi blade rip saws ensure that every piece meets stringent quality standards. Maintaining tight tolerances leads to smoother downstream processes like edge banding, drilling, and assembly — crucial for delivering consistent final products.

Solid Wood and Composite Flooring Production

Precision-cut flooring panels are essential for both aesthetic and functional performance.

Wood plate multi blade rip saw machines play a critical role in ensuring that every piece of flooring — whether solid hardwood, engineered wood, or laminate flooring — fits seamlessly.

High-Speed, High-Precision Cuts

These machines easily handle long boards and thin panels, slicing them into perfect strips at high speeds.

By supporting both massive production runs and custom orders, manufacturers can stay flexible while maintaining operational efficiency.

Material Flexibility

Whether dealing with dense hardwoods or composite substrates, wood plate multi blade rip saws adjust quickly to various kinds of wood substrates.

Wooden Crate and Packaging Box Manufacturing

Beyond traditional furniture and flooring, wood plate multi blade rip saw machines are essential in the packaging industry as well.

Rapid Component Production

Packaging manufacturers often need custom-sized slats and panels for crates, pallets, and wooden boxes.

The ability to rip multiple components simultaneously makes multi blade saws ideal for meeting large, varied orders efficiently.

Cost-Efficient Manufacturing

Reducing material waste is a major advantage. With precise kerf control and optimized cutting layouts, wood plate multi blade rip saws enable manufacturers to maximize board utilization, significantly cutting raw material costs.

Laminated Timber and Frame Production

Specialized applications, such as laminated timber products, bed frames, and photo frames, benefit greatly from the precision of a multi blade saw.

Uniformity for Assembly

When producing frames and laminated components, consistent dimensions are critical to ensuring proper assembly and long-term structural integrity. Wood plate multi blade rip saw machines deliver the uniform cuts necessary for high-end specialty products.

Supporting Customization

Manufacturers offering bespoke sizes or custom shapes appreciate the flexibility of blade adjustments, which allows quick transitions between batch specifications without lengthy setup times.

Advantages Across Industries

The success of the wood plate multi blade rip saw machine across different sectors is no coincidence. Key advantages include:

• High Efficiency: Cutting multiple parts at once slashes processing times.

• Precision and Stability: Optional servo-controlled systems ensure consistent quality.

• Reduced Waste: Optimized cuts save material and lower production costs.

• Flexible Integration: Compatible with both manual feeding and automated production lines.

Whether you’re producing flooring, cabinetry, or shipping crates, a wood plate multi blade rip saw machine boosts operational efficiency and enhances overall product quality.

In industries where speed, precision, and material savings are crucial, the wood plate multi blade rip saw machine stands out as a top-performing solution.

Furniture makers, flooring manufacturers, and packaging companies alike can realize significant improvements in output and profitability by integrating these powerful machines into their operations.

As demand for higher productivity and customized products grows, investing in advanced cutting technology like the wood plate multi blade rip saw is no longer optional — it’s a strategic necessity.