What Is Panel Multi Blade Rip Saw Machine and Where Can It Be Used?

Learn about panel multi blade rip saws — powerful machines that drive efficiency in flooring, furniture, and packaging production with precise, high-speed cutting.

In today’s woodworking and manufacturing industries, efficiency and precision are no longer optional — they are mandatory. The panel multi blade rip saw machine has emerged as a crucial solution for businesses seeking higher output and consistent quality. By automating the ripping of panels into multiple strips in a single pass, these machines dramatically enhance productivity.

This article explores what a panel multi blade rip saw machine is and where it can be applied, helping manufacturers understand its value in modern production lines.

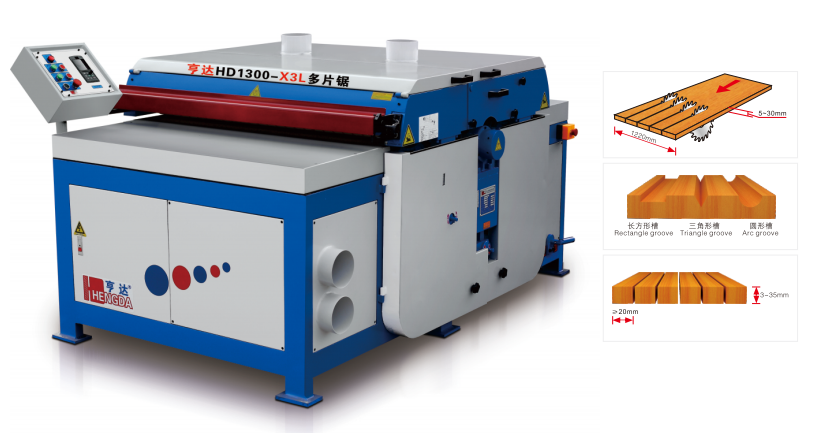

What Is Panel Multi Blade Rip Saw Machine?

A panel multi blade rip saw is a heavy-duty cutting machine designed to split large wood-based panels into multiple pieces with one feed. Unlike traditional single-blade saws, it uses a series of blades mounted on a spindle, spaced according to the desired output dimensions.

Key Features of Multi Blade Saws Machine

• High-speed cutting: Simultaneous ripping significantly shortens processing time.

• Precision and stability: Each piece of wood plate is cut precisely and the efficiency is stable.

• Adaptability: Capable of handling long, broken, thick, and thin panels efficiently.

• Flexible operation: Available for manual feeding or full integration into automated production lines.

The combination of speed, accuracy, and adaptability makes panel multi blade rip saws a staple in industries requiring mass customization and rapid throughput.

Where Panel Multi Blade Rip Saw Machine Is Used

The versatility of panel multi blade rip saw machine enables their application across multiple sectors. Manufacturers looking to optimize workflows and cut material costs find these machines indispensable.

Panel multi blade rip saws play a pivotal role in the production of cabinetry, wardrobes, office furniture, and shelving units. Their ability to rip particleboard, MDF, and plywood into precise sizes ensures consistent quality for downstream processes like edge banding and drilling.

For high-volume panel furniture manufacturers, integrating a panel multi blade rip saw boosts production capacity without sacrificing accuracy.

In solid wood composite flooring and laminate flooring manufacturing, precision in panel sizing directly impacts product performance and visual appeal.

Multi blade saws guarantee tight tolerances and clean edges, enabling flooring panels to fit perfectly during installation. Moreover, the machines’ capacity to handle thin and thick materials expands their usefulness across various flooring product lines.

Wooden Packaging and Crate Manufacturing

Industries producing wooden packaging boxes, pallets, and shipping crates benefit greatly from the speed and flexibility of panel multi blade rip saw machine.

Manufacturers can quickly cut components in bulk, accommodating customized packaging dimensions with minimal waste. Especially for businesses handling diverse order profiles, the ability to adjust blade spacing makes these saws essential for agile production.

Laminated Timber and Specialized Wood Products

Producers of laminated timber, bed frames, and picture frames also rely on panel multi blade rip saw machine to ensure high output and consistent part sizing.

The machine’s robust design and automation options — such as suction-based loading systems — enable seamless processing even for specialty wood products that require delicate handling.

Advantages of Integrating a Panel Multi Blade Rip Saw Machine

Choosing the right equipment can redefine a company’s manufacturing capabilities. Panel multi blade rip saws offer several critical advantages:

• Increased Throughput: Multiplied cutting operations with every pass drastically reduce lead times.

• Material Savings: Precise cuts mean less material waste and higher overall yield.

• Labor Efficiency: Automation options like push-type feeding and gantry loaders minimize manual labor and reduce operating costs.

• Enhanced Quality Control: Stable and uniform cuts maintain consistent product standards across production batches.

By incorporating panel multi blade rip saw machine, manufacturers position themselves to meet growing market demands for speed, flexibility, and customization.

As markets evolve and customer expectations heighten, manufacturers must leverage technology that delivers superior performance and versatility. A panel multi blade rip saw is not just a machine; it is a strategic investment that powers scalable, high-quality production across a wide range of industries.

For companies aiming to stay competitive in flooring, furniture, packaging, or specialized wood product sectors, integrating a panel multi blade rip saw machine is a clear path to enhanced productivity and profitability.