1 CNC Box Making Machine + 1 Digital Printing Press = The Ultimate Carton Factory Combo

The key to upgrading a carton factory lies not in “more equipments,” but in “the right equipment.” Nowadays, the cardboard box market is changing faster than it did over the past decade combined. Raw material costs are rising, competition is intensifying, profits are shrinking, and orders are becoming increasingly scattered. Should we take on these scattered orders? Customers demand multiple sizes, small batches, rush orders, and customization—and they frequently change dimensions and quantities on the fly. The cost of switching die-cutting plates on standard machines simply can’t be absorbed!

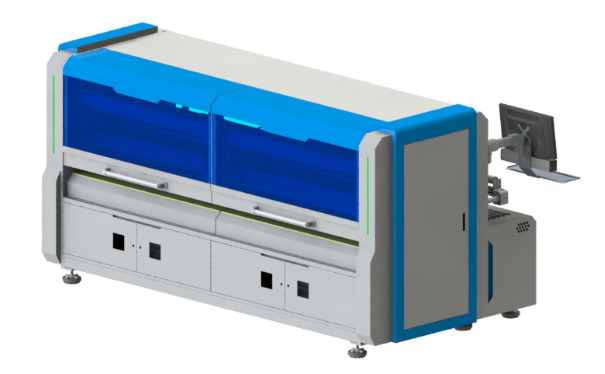

Against this backdrop, CNC box making machines have become the true core production equipment for carton factories: they can complete actions like slotting, creasing, cutting, separating lines, punching holes, and applying adhesive in a single pass, and switch to the next specification within seconds—making them the absolute champions in a small-batch production environment. Even when paired with a digital printing press, the carton factory can upgrade from “only capable of producing standard boxes” to a powerful model that “takes orders of any sizes and any shapes and handles custom jobs.”

Why CNC Box Making Machine Is Important in carton factories?

Single-pass feeding completes the entire process, reconfiguring the production chain.

Traditional corrugated box production requires multiple machines: slotting machines, creasing machines, paper cutters, paper separators… Each process step can introduce deviations, labor waste, and time loss. In contrast, CNC corrugated box machines integrate the entire process into a single line, completing production with a single sheet feed: Perforation, Slotting, Cross Creasing, Longitudinal Creasing, Cutting, Punching, Slitting, Gluing, Simple Printing. The entire production line’s logic has shifted from “multiple machines in series” to “digital one-step production”.

3s changeovers enable carton manufacturers to handle mixed-model orders for the first time.

Traditional machine changeovers are technical tasks: adjusting blades, setting creasing lines, test-cutting, aligning… Just a dozen orders a day leaves workers scrambling. But CNC box making machines require no manual adjustments. All blades, creasing wheels, and cutting modules are servo-automatically positioned: Input dimensions → Execute program → Direct processing.

Changeover time can be controlled to around 3 seconds. This means: the carton factory can effortlessly cut 100+ different sizes in a single day—no downtime, no skilled labor required.

Small Batches Orders Needs CNC Box Making Machine

Handle the multi-SKU demands of e-commerce and branded packaging

E-commerce sellers may require over a dozen box types in a single day; furniture factories and logistics hubs also need custom-sized cartons on demand. Traditional carton manufacturers often refuse small orders because of the high costs of the molds, but CNC box making machines can instantly switch box shapes and dimensions, turning these orders into margin business. Small orders are no longer a hassle—but they’re an opportunity.

No human dependency—perfect for beginners

Carton box factories commonly face a shortage of skilled workers. CNC box making machines, however, do not rely on experience, allowing ordinary workers to operate them after simple training. The equipment automatically calculates cutting positions, creasing locations, and cutting depths, ensuring stability and consistency. This advantage is particularly crucial for factories facing future labor shortages and rising labor costs. Exceptionally high precision, especially for multiple batches of individual orders, where accuracy no longer depends on the “craftsmanship of the master.”

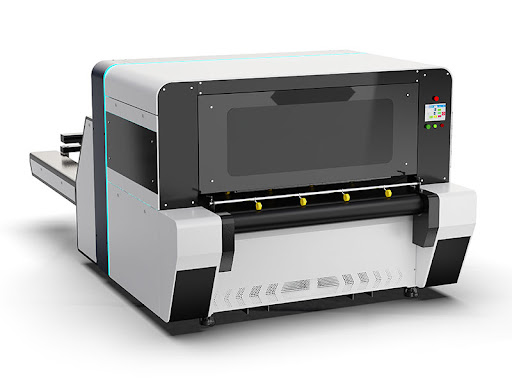

Combined With Digital Printing Machine, Achieving Coverage For Large & Small Order

When handling small-batch orders, CNC carton machines swiftly cut boxes while digital printers produce prints on demand. The entire process requires no waiting, no plate making, and no machine setup. This enables carton manufacturers to achieve for the first time: every order is profit, eliminating the need to pick and choose jobs.

For medium-volume production, the two machines operate independently without occupying each other’s workstations: the printer runs continuously at high speed while the CNC carton machine cuts and forms at a steady rhythm. This setup achieves higher efficiency than traditional single-machine processes, with enhanced stability.

Traditional factories often decline rush orders. But the CNC die-cutting machine + digital printing press combo delivers: cut anytime, print anytime, ship anytime. These urgent orders often yield the highest profits and are the most effective way to lock in customers.

Conclusion

No matter how the carton market evolves, no matter how diverse customer orders become, the most critical factors for carton manufacturers in the future will be flexibility, responsiveness, and consistent quality. And the core equipment that delivers all this? Just one: the CNC box making machine.

Digital printing presses aren’t the main attraction, but they serve as a “capability booster” that expands your business scope. Combined, these two form the optimal equipment setup for carton factories over the next decade: Large orders rely on speed, small orders on flexibility, urgent orders on responsiveness, and custom orders on printing. This truly enables you to handle both large and small orders with equal proficiency, securing consistently high profits.