Honeycomb Paper Stretching and Drying Machine: Versatile Solution for Eco Material Processing

The Honeycomb Paper Stretching and Drying Machine is designed for the forming, shaping, and stabilizing of honeycomb paper after expansion. It is widely used in various industries, including eco-friendly panel manufacturing, composite door production, lightweight furniture panels, packaging materials, and decorative building panels. With optional cross and longitudinal cutting modules, the honeycomb paper stretching and drying machine provides an efficient, flexible, and clean processing solution for modern manufacturers pursuing sustainable production.

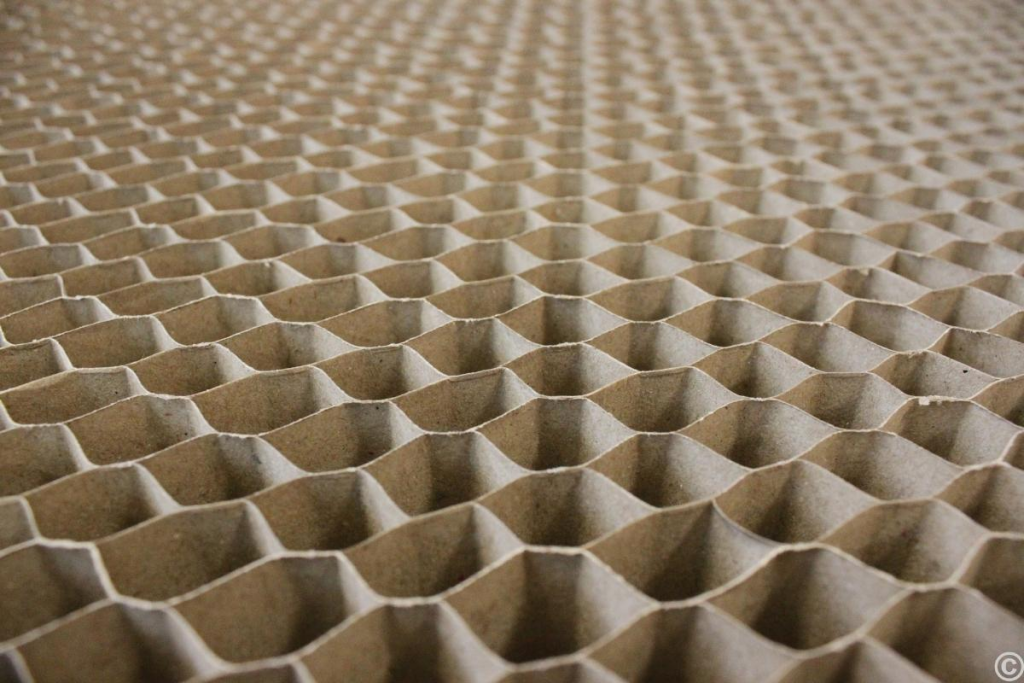

Stable Structure for Precise Stretching

At the heart of the machine is a heavy-duty welded steel frame that ensures excellent rigidity and long-term stability. The extended feeding table and dual servo-driven rollers provide smooth and synchronized feeding, preventing material distortion and maintaining uniform stretching results.

This precision is essential for applications that require flat, well-shaped honeycomb sheets — whether for eco doors, furniture panels, or lightweight sandwich boards.

Energy-Efficient and Uniform Drying

Drying determines the dimensional stability and bonding quality of honeycomb materials.

The machine features nine heating tubes (2 kW each) arranged in an optimized top-and-bottom configuration (4+5) to ensure even temperature distribution. The chamber is insulated with fireproof cotton, minimizing heat loss and saving energy while keeping the working environment comfortable.

This makes it ideal for continuous drying processes in packaging, furniture, or decorative panel production.

Optional Cutting System for Integrated Processing

To meet different production requirements, the honeycomb paper stretching machine can be equipped with cross-cutting and longitudinal slitting functions. With one guillotine blade and four circular knives, the machine performs clean, dust-free cuts — no suction system required. This optional feature transforms it from a stretching-drying unit into a multi-functional honeycomb paper processing system, perfect for lines producing ready-to-use panels or packaging inserts.

Multiple Applications Across Industries

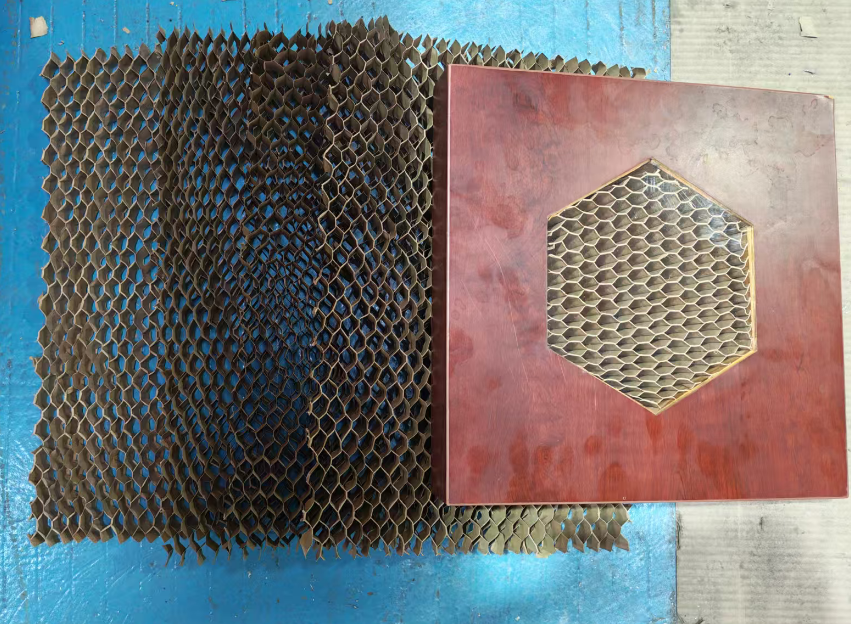

Eco Furniture & Composite Doors

Ensures uniform stretching and shaping of honeycomb cores used in interior doors, wardrobes, and lightweight furniture panels, reducing deformation and improving adhesion.

Packaging and Buffer Materials

Used for honeycomb paper cushion production, ensuring precise expansion and stable drying for packaging inserts and shock-absorbing panels.

Green Building & Decorative Panels

Ideal for architectural honeycomb materials, such as wall panels, ceilings, and eco partition boards, providing smooth surfaces and stable internal bonding.

Conclusion

The Honeycomb Paper Stretching and Drying Machine represents a new generation of intelligent forming equipment for the eco-material industry. By integrating precise servo control, stable heating, and modular functionality, it enables manufacturers to achieve accurate stretching, consistent drying, and optional dust-free cutting — all within one efficient system.

Its versatility makes it suitable for a wide range of production fields, including furniture panels, composite interior doors, eco-friendly packaging materials, architectural decoration panels, and other lightweight structures that rely on honeycomb paper for strength and sustainability.

Whether you are upgrading an existing production system or building a new eco-material line, the Honeycomb Paper Stretching and Drying Machine is a dependable solution to enhance productivity and product consistency — helping you stay competitive in a market that demands both innovation and sustainability.